การลดความสูญเปล่าในกระบวนการจัดการคำสั่งซื้อจากการพัฒนาระบบการวางแผนทรัพยากรองค์กร กรณีศึกษา บริษัทเอบีซี

Main Article Content

บทคัดย่อ

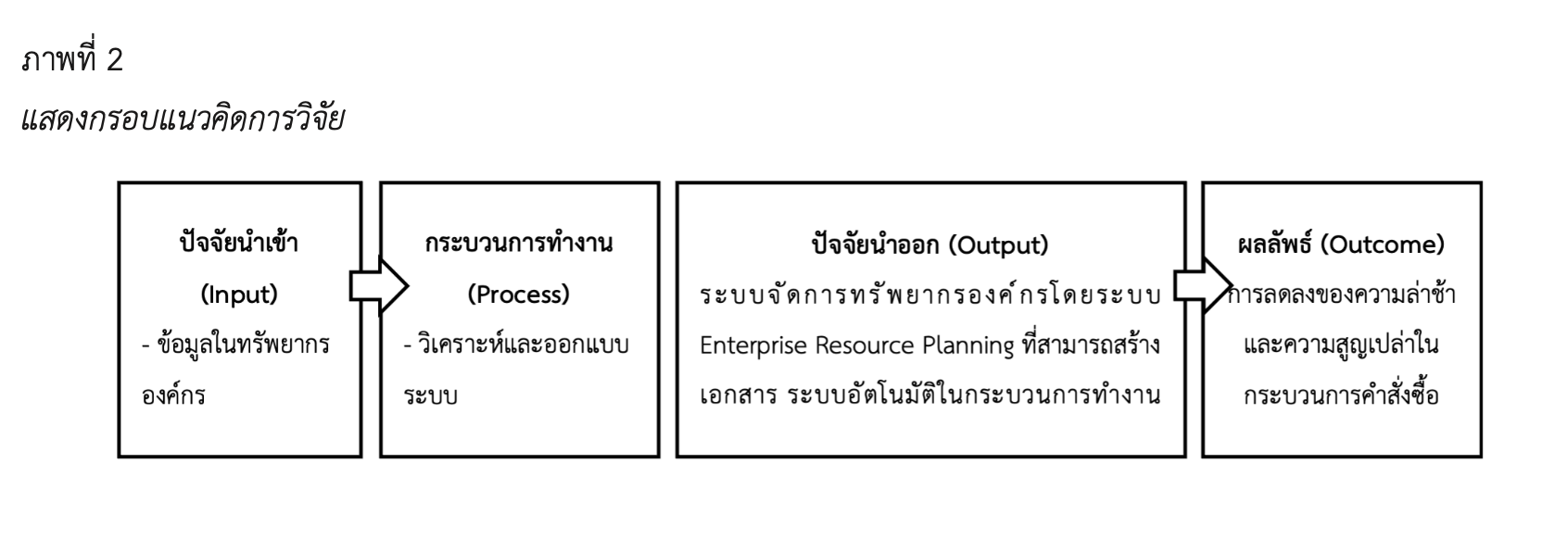

งานวิจัยนี้จัดทำเพื่อศึกษากระบวนการจัดการคำสั่งซื้อเดิมของกรณีศึกษาบริษัท เอบีซี และเพื่อลดความสูญเปล่าที่เกิดขึ้นในกระบวนการจัดการคำสั่งซื้อโดยการสร้างระบบการวางแผนทรัพยากรองค์กร และเสนอแนวทางการประยุกต์ใช้ในองค์กร กลุ่มตัวอย่าง คือ ระยะเวลาดำเนินการของธุรกรรมในกระบวนการจัดการคำสั่งซื้อจากรายงานผลการดำเนินงานการผลิตและบริหารงานคลังสินค้า เดืือน มกราคม 2567 จำนวนทั้งสิ้น 149 คำสั่งซื้อ ใช้ผังก้างปลา การวิเคราะห์ด้วยหลักการทำงาน ECRS (การกำจัด, การรวมกัน, การจัดใหม่, การทำให้ง่าย) การออกแบบผังงาน และแผนภาพแสดงการไหลของข้อมูลและการสร้างระบบการวางแผนทรัพยากรองค์กร เป็นเครื่องมือวิจัยและวิเคราะห์โดยใช้สถิติพรรณนาด้วยความถี่และร้อยละ

ผลการวิจัยพบว่า

ปัจจุบันบริษัทกำลังประสบปัญหาความล่าช้าในกระบวนการคำสั่งซื้ออย่างต่อเนื่อง จากการไม่เชื่อมต่อของข้อมูลเแต่ละแผนกใช้ระบบที่แยกกัน ของระบบควบคุมการผลิตและสินค้าคงคลัง และระบบบัญชีสำเร็จรูป เมื่อข้อมูลไม่ได้เชื่อมต่อกัน เกิดการทำงานซ้ำซ้อนและไม่สอดคล้องกัน เกิดความล่าช้าในการสื่อสารข้อมูลและการทำงานที่ซ้ำซ้อน สาเหตุหลักที่ทำให้เกิดความสูญเปล่าในกระบวนการจัดการคำสั่งซื้อคือ การขาดการเชื่อมโยงกันของระบบบริหารจัดการข้อมูลสารสนเทศในบริษัท จึงมีการวิเคราะห์และออกแบบระบบโดยแผนภาพการไหลของข้อมูล มีผู้ที่เกี่ยวข้องต่อระบบ 8 ส่วน ได้แก่ ลูกค้า ฝ่ายขาย ฝ่ายคลังสินค้า ฝ่ายจัดซื้อ ฝ่ายการบัญชีและการเงิน ฝ่ายการจัดการทรัพยากรมนุษย์ ฝ่ายผลิต ฝ่ายขนส่ง ได้นำหลักการ ECRS เพื่อลดความสูญเปล่าได้ถึง 20 ขั้นตอน จึงเสนอแนวทางการประยุกต์ใช้ในกระบวนการจัดการคำสั่งซื้อจากการสร้างแบบจำลองระยะเวลาดำเนินการในการปรับปรุงระยะเวลาในการกระบวนการ 263.30 นาที เหลือ 137.30 นาที ลดลง 129.57 นาทีต่อคำสั่งซื้อ คิดเป็นร้อยละ 47.94 ต่อคำสั่งซื้อ เมื่อนำมาใช้จริงจำนวนคำสั่งซื้อที่ล่าช้าก่อนปรับปรุง 75 คำสั่งซื้อ เหลือ 4 คำสั่งซื้อ ลดลง 71 คำสั่งซื้อ คิดเป็นร้อยละ 94.67 ในขณะที่ระยะเวลาความล่าช้าคำสั่งซื้อก่อนปรับปรุง 1,964 นาที เหลือ 37 นาที ลดลง 1,927 นาที คิดเป็นร้อยละ 98.12

Article Details

เอกสารอ้างอิง

กฤษฎิมา เบญจประภาพร. (2554). การวางแผนและควบคุมวัสดุโดยใช้ระบบ SAP: กรณีศึกษาบริษัทผลิตสื่อสิ่งพิมพ์ [วิทยานิพนธ์ปริญญามหาบัณฑิต, มหาวิทยาลัยธุรกิจบัณฑิตย์]. https://doi.nrct.go.th/ListDoi/listDetail?Resolve_DOI=10.14458/DPU.the.2011.70

คาซึมะ บัน, และฮิโตชิ อิโต. (2546). สู่การเป็นผู้นำในการใช้ ERP (ฤทธาภรณ์ และคณะ, ผู้แปล). สมาคมส่งเสริมเทคโนโลยี (ไทย-ญี่ปุ่น).

ฝ่ายผลิตและบริหารงานคลังสินค้า กรณีศึกษาบริษัท เอบีซี. (2566). รายงานผลการดำเนินงานการผลิตและบริหารงานคลังสินค้า สิงหาคม 2566. บริษัท เอบีซี.

ฝ่ายผลิตและบริหารงานคลังสินค้า กรณีศึกษาบริษัท เอบีซี. (2567). รายงานผลการดำเนินงานการผลิตและบริหารงานคลังสินค้า มกราคม 2567. บริษัท เอบีซี.

Alsharari, N. M., Al-Shboul, M., & Alteneiji, S. Z. (2020). Implementation of cloud ERP in the SME: Evidence from UAE. Journal of Small Business and Enterprise Development, 27(2), 299-327. https://doi.org/10.1108/JSBED-01-2019-0007:contentReference[oaicite:0]{index=0}

Bocij, P., Greasley, A., & Hickie, S. (2018). Business information systems: Technology, development, and management for the modern business. Pearson.

Bowersox, D. J., Closs, D. J., & Cooper, M. B. (2012). Supply chain logistics management (4th ed.). McGraw-Hill.

Christopher, M. (2016). Logistics & supply chain management. Pearson UK.

Krajewski, L. J., Ritzman, L. P., & Malhotra, M. K. (2019). Operations management: Processes and supply chains (12th ed.). Pearson Education.

Liker, J. K. (2004). The Toyota way: 14 management principles from the world’s greatest manufacturer. McGraw-Hill.

Mentzer, J. T. (2001). Supply chain management. Sage Publications.

Monczka, R., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2020). Purchasing and supply chain management (7th ed.). Cengage Learning.

Monk, E., & Wagner, B. (2013). Concepts in enterprise resource planning (4th ed.). Cengage Learning.

Womack, J. P., & Jones, D. T. (1996). Lean thinking: Banish waste and create wealth in your corporation. Simon and Schuster.