Carbon-based Solid Acid Catalysts for the Reduction of Fatty Acid Content in Waste Cooking Oil

Main Article Content

Abstract

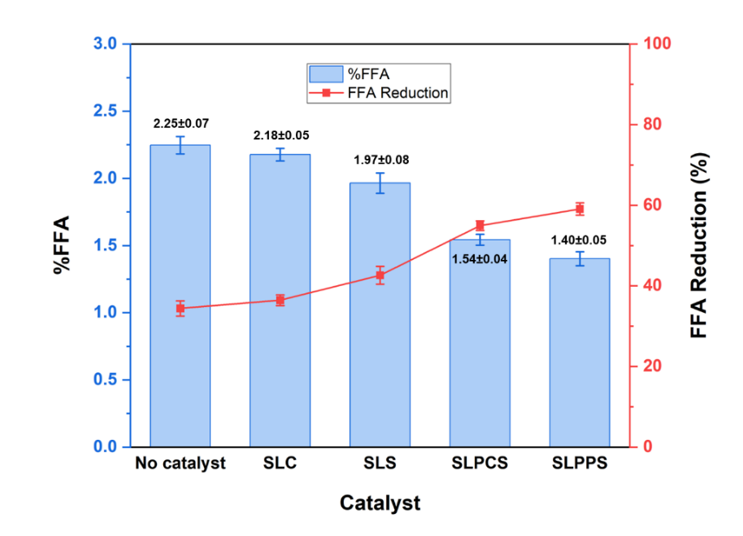

This research prepared carbon-based solid acid catalysts from sugarcane leaves via hydrothermal carbonization-sulfonation processes in combination with perchloric acid and phosphoric acid. The functional groups were examined by Fourier Transform Infrared (FT-IR) Spectroscopy and found similar characteristics of all the three solid acid catalysts, which consisted of hydroxyl groups (−OH), carboxyl groups (−COOH), and sulfonic groups (−SO3H) showing acidic properties on the catalysts. The prepared solid acids had total acid density between 2.26-3.71 mmol/g and sulfonic groups contents between 0.428-0.768 mmol/g. When the solid acid catalysts were tested for the reduction of free fatty acids in vegetable oils with high free fatty acid content prepared by blending palm oil with oleic acid, via esterification with methanol, it was found that the ratio of methanol to starting oil, reaction temperature, and reaction time affected the reduction of free fatty acids. The catalytic reaction in used vegetable oil was tested by varying parameters such as methanol:oil molar ratio, temperature, reaction time, catalyst types, and amounts of catalyst. It was found that the catalyst prepared with phosphoric and sulfuric acids was the most effective in reducing the amount of free fatty acids in used vegetable oil, having the percentage of free fatty acids of 0.95 after 5 hours when using the carbon-based solid acid catalyst (SLPPS) 3% by weight of the starting oil.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

The Journal of Science and Science Education (JSSE) retain the right of all articles published in JSSE. The coresponding author or the authorized person on behalf of the authors must send the complete Copyright Transfer Form to JSSE before any article get published in JSSE.

Copyright Transfer Form

The JSSE request the coresponding author or the authorized person on behalf of the authors upload the manuscript under the together with the Copyright Transfer Form under the supplementary data. The guidline for uploading both manuscript and Copyright Transfer Form is shown below:

1. Upload the manuscript in the sub-menu, Article Component > Article Text.

2. Upload the the Copyright Transfer Form in the sub-menu, Article Component > Other.

Download Copyright Transfer Form

References

Atabani, A. E., Silitonga, A. S., Badruddin, I. A., Mahlia, T. M. I., Masjuki, H. H. and Mekhilef, S. (2012). A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renewable and Sustainable Energy Reviews, 16(4), 2070-2093.

Bajpai, D. and Tyagi, V. K. (2006). Biodiesel: Source, Production, Composition, Properties and Its Benefits. Journal of Oleo Science, 55(10), 487-502.

Changmai, B., Vanlalveni, C., Ingle, A. P., Bhagat, R. and Rokhum, S. L. (2020). Widely used catalysts in biodiesel production: a review. RSC Advances, 10(68), 41625-41679.

Chen, D., Tang, W., Wang, H., Sheng, Y., Tan, X., Shi, Y., Fan, W. and Ge, S. (2023). Phosphoric acid pretreatment of poplar to optimize fermentable sugars production based on orthogonal experimental design. Frontiers in Chemistry, 11, 1119215.

Ding, J., He, B. and Li, J. (2011). Biodiesel Production from Acidified Oils via Supercritical Methanol. Energies, 4(12), 2212-2223.

Erdem, B. and Azko, Ç. (2017). B–SBA-15–SO3H: a versatile mesoporous catalyst. Journal of Porous Materials, 24(5), 1237-1246.

Guo, Y., Delbari, S. A., Sabahi Namini, A., Le, Q. V., Park, J. Y., Kim, D., Varma, R. S., Jang, H. W., T-Raissi, A., Shokouhimehr, M. and Li, C. (2023). Recent developments in solid acid catalysts for biodiesel production. Molecular Catalysis, 547, 113362.

He, Y.-C., Liu, F., Gong, L., Lu, T., Ding, Y., Zhang, D.-P., Qing, Q. and Zhang, Y. (2015). Improving Enzymatic Hydrolysis of Corn Stover Pretreated by Ethylene Glycol-Perchloric Acid-Water Mixture. Applied Biochemistry and Biotechnology, 175(3), 1306-1317.

Hsiao, M.-C., Liao, P.-H., Lan, N. V. and Hou, S.-S. (2021). Enhancement of Biodiesel Production from High-Acid-Value Waste Cooking Oil via a Microwave Reactor Using a Homogeneous Alkaline Catalyst. Energies, 14(2), 437.

Ighalo, J. O., Akaeme, F. C., Georgin, J., de Oliveira, J. S. and Franco, D. S. P. (2025). Biomass Hydrochar: A Critical Review of Process Chemistry, Synthesis Methodology, and Applications. Sustainability, 17(4), 1660.

Kang, S., Zhang, G., Yang, X., Yin, H., Fu, X., Liao, J., Tu, J., Huang, X., Qin, F. G. F. and Xu, Y. (2017). Effects of p-Toluenesulfonic Acid in the Conversion of Glucose for Levulinic Acid and Sulfonated Carbon Production. Energy & Fuels, 31(3), 2847-2854.

Laohapornchaiphan, J. (2021). Preparation of carbon-based solid acid catalysts for esterification of oleic acid (in Thai). Proceedings of the 12th Rajamangala Surin National Conference (pp. A104-A115). September 16-17, 2021. Surin: Rajamangala University of Technology Isan SURIN Campus.

Laohapornchaiphan, J., Smith, C. B. and Smith, S. M. (2017). One-step Preparation of Carbon-based Solid Acid Catalyst from Water Hyacinth Leaves for Esterification of Oleic Acid and Dehydration of Xylose. Chemistry – An Asian Journal, 12(24), 3178-3186.

Leung, D. Y. C., Wu, X. and Leung, M. K. H. (2010). A review on biodiesel production using catalyzed transesterification. Applied Energy, 87(4), 1083-1095.

Li, Y. and Zeng, D. (2017). Synthesis and characterization of flower-like carbon spheres solid acid from glucose for esterification. Materials Letters, 193, 172-175.

Mahajan, A. and Gupta, P. (2020). Carbon-based solid acids: a review. Environmental Chemistry Letters, 18(2), 299-314.

Marchetti, J. M. and Errazu, A. F. (2008). Esterification of free fatty acids using sulfuric acid as catalyst in the presence of triglycerides. Biomass and Bioenergy, 32(9), 892-895.

McCarthy, P., Rasul, M. G. and Moazzem, S. (2011). Comparison of the performance and emissions of different biodiesel blends against petroleum diesel. International Journal of Low-Carbon Technologies, 6(4), 255-260.

Meher, L. C., Vidya Sagar, D. and Naik, S. N. (2006). Technical aspects of biodiesel production by transesterification—a review. Renewable and Sustainable Energy Reviews, 10(3), 248-268.

Mishra, V. K. and Goswami, R. (2018). A review of production, properties and advantages of biodiesel. Biofuels, 9(2), 273-289.

Nakajima, K. and Hara, M. (2012). Amorphous Carbon with SO3H Groups as a Solid Brønsted Acid Catalyst. ACS Catalysis, 2(7), 1296-1304.

Parangi, T. and Mishra, M. K. (2020). Solid Acid Catalysts for Biodiesel Production. Comments on Inorganic Chemistry, 40(4), 176-216.

Peng, L., Philippaerts, A., Ke, X., Van Noyen, J., De Clippel, F., Van Tendeloo, G., Jacobs, P. A. and Sels, B. F. (2010). Preparation of sulfonated ordered mesoporous carbon and its use for the esterification of fatty acids. Catalysis Today, 150(1), 140-146.

Pi, Y., Liu, W., Wang, J., Peng, G., Jiang, D., Guo, R. and Yin, D. (2022). Preparation of Activated Carbon-Based Solid Sulfonic Acid and Its Catalytic Performance in Biodiesel Preparation. Frontiers in Chemistry, 10, 1-10.

Saha, R. and Goud, V. V. (2015). Ultrasound assisted transesterification of high free fatty acids karanja oil using heterogeneous base catalysts. Biomass Conversion and Biorefinery, 5(2), 195-207.

Schneider, L. T., Bonassa, G., Alves, H. J., Meier, T. R. W., Frigo, E. P. and Teleken, J. G. (2019). Use of rice husk in waste cooking oil pretreatment. Environmental Technology, 40(5), 594-604.

Sevilla, M. and Fuertes, A. B. (2009). The production of carbon materials by hydrothermal carbonization of cellulose. Carbon, 47(9), 2281-2289.

Sharma, H. B., Sarmah, A. K. and Dubey, B. (2020). Hydrothermal carbonization of renewable waste biomass for solid biofuel production: A discussion on process mechanism, the influence of process parameters, environmental performance and fuel properties of hydrochar. Renewable and Sustainable Energy Reviews, 123, 109761.

Toda, M., Takagaki, A., Okamura, M., Kondo, J. N., Hayashi, S., Domen, K. and Hara, M. (2005). Biodiesel made with sugar catalyst. Nature, 438(7065), 178-178.

Trubiano, G., Borio, D. and Errazu, A. (2007). Influence of the operating conditions and the external mass transfer limitations on the synthesis of fatty acid esters using a Candida antarctica lipase. Enzyme and Microbial Technology, 40(4), 716-722.

Wan Osman, W. N. A., Rosli, M. H., Mazli, W. N. A. and Samsuri, S. (2024). Comparative review of biodiesel production and purification. Carbon Capture Science & Technology, 13, 100264.

Wang, Q., Wang, Z., Shen, F., Hu, J., Sun, F., Lin, L., Yang, G., Zhang, Y. and Deng, S. (2014). Pretreating lignocellulosic biomass by the concentrated phosphoric acid plus hydrogen peroxide (PHP) for enzymatic hydrolysis: Evaluating the pretreatment flexibility on feedstocks and particle sizes. Bioresource Technology, 166, 420-428.

Woiciechowski, A. L., Neto, C. J. D., de Souza Vandenberghe, L. P., de Carvalho Neto, D. P., Sydney, A. C. N., Letti, L. A. J., Karp, S. G., Torres, L. A. Z. and Soccol C. R. (2020). Lignocellulosic biomass: Acid and alkaline pretreatments and their effects on biomass recalcitrance–Conventional processing and recent advances. Bioresource Technology, 304, 122848.

Wong, S. F., Tze, T. A. N. and Chin, Y. H. (2023). Pre-treatment of waste cooking oil by combined activated carbon adsorption and acid esterification for biodiesel synthesis via two-stage transesterification. Biofuels, 14(9), 967-977.

Zavarize, D. G., Vieira, G. E. G. and de Oliveira, J. D. (2023). Kinetics of free fatty acids esterification in waste frying oil using novel carbon-based acid heterogeneous catalyst derived from Amazonian Açaí seeds – Role of experimental conditions on a simpler pseudo first-order reaction mechanism. Catalysis Communications, 180, 106716.